Amore made 2021

Amore Made had been engaged by Be-Architecture & Dome Building to

develop and fabricate a new range of window and door profiles for a heritage

listed residential property in Melbourne’s south east suburbs. From the

initial design concept to installation, the evolution of these profiles were

influenced by many factors, such as choice of material, durability and

structural integrity, often guided by the aesthetic, but always respecting the

performance and functionality.

Being a new design meant we had to develop the numerous custom

components of the system, from the offset pivot and floor spring which

enabled the controlled mechanics of the door leaf, to the jambs with

integrated push in seals and scalloped glazing beads, along with the custom

sills, providing a full weather seal to all window and door perimeters.

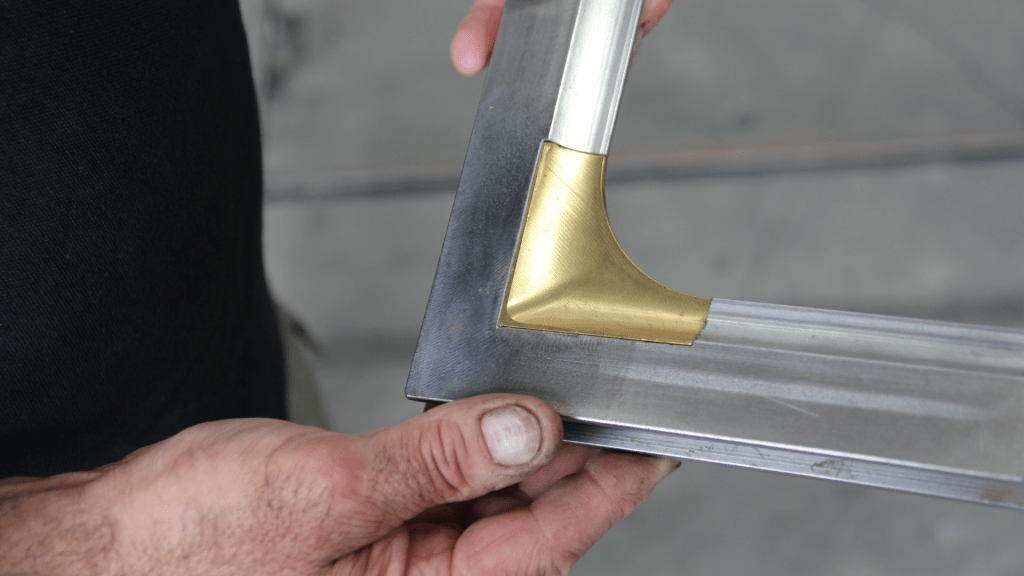

The choice of brass as the material came about from the inherent

limitations and costs of machining steel, but more for its intrinsic qualities,

as the aged patina finish seamlessly engaged with its surrounding materials

palette and architectural features.

Design development

The original specifications for the window profiles was to be as blackened mild steel, though, due to steel’s material limitations against the elements combined with the cost of production (as each profile would have had to be machined from full lengths of stock), we were unable to meet the desired budget and warranty requirements of the project. It was then that we put forward the idea of producing the profiles by extruding brass as it worked out to be more cost effective and was far more resistant to ageing as opposed to mild steel. Though this decision came with its own set of unique engineering considerations throughout the project.

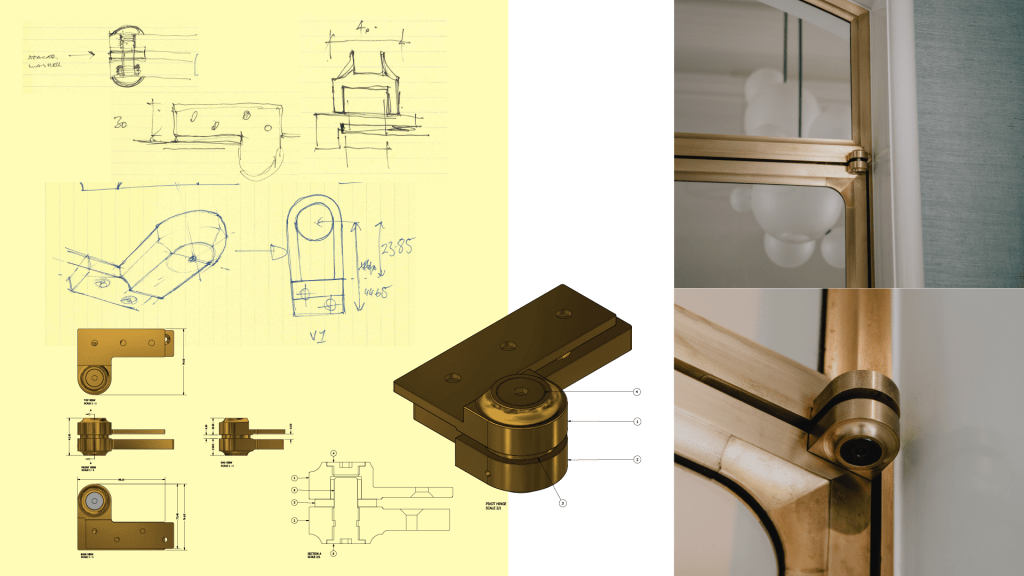

Offset pivot hinge

One of the custom components we had to design for the brass profiles was the offset pivot system for all the doors. Visually integrating the pivot-hinge in with the brass profiles was done by replicating the same scalloped design features around the pivot pin and bearing, as these locations of the hinge needed more material as it would house bearings, threaded sections and end caps.

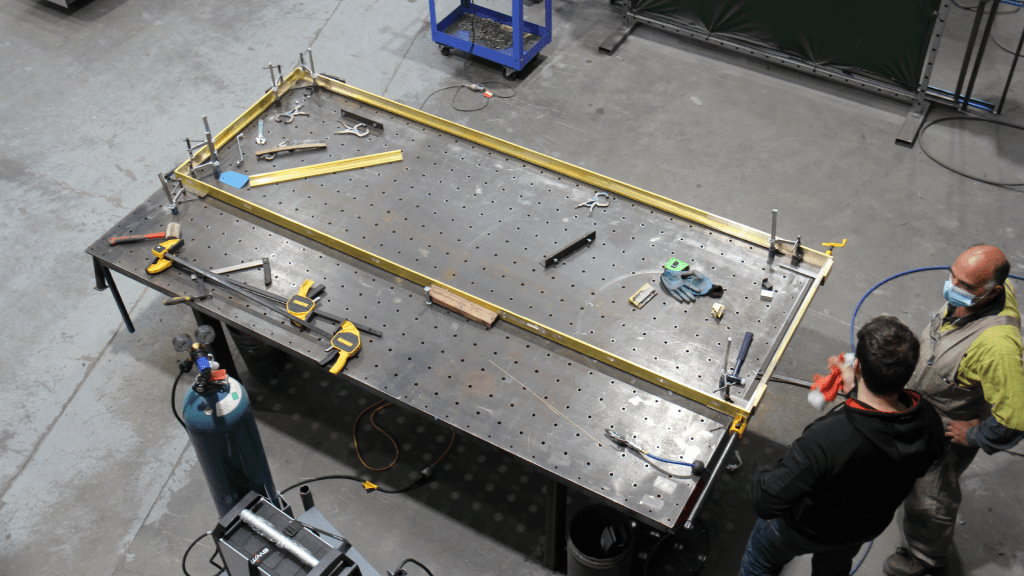

Fabrication

From the beginning of the development phase the design team and fabrication team worked closely and collaboratively when problem solving fabrication and installation details. This approach led to clear and precise communication throughout the drawings that would cover welding, fixing, and finishing details, right through to installation documentation for the builders on site.

Because working with brass at this scale was quite novel, we were regularly adapting minor features of the designs to increase the strength and stiffness of the brass profiles to ensure that each window and door would operate even with the fluctuations of Melbourne’s weather.